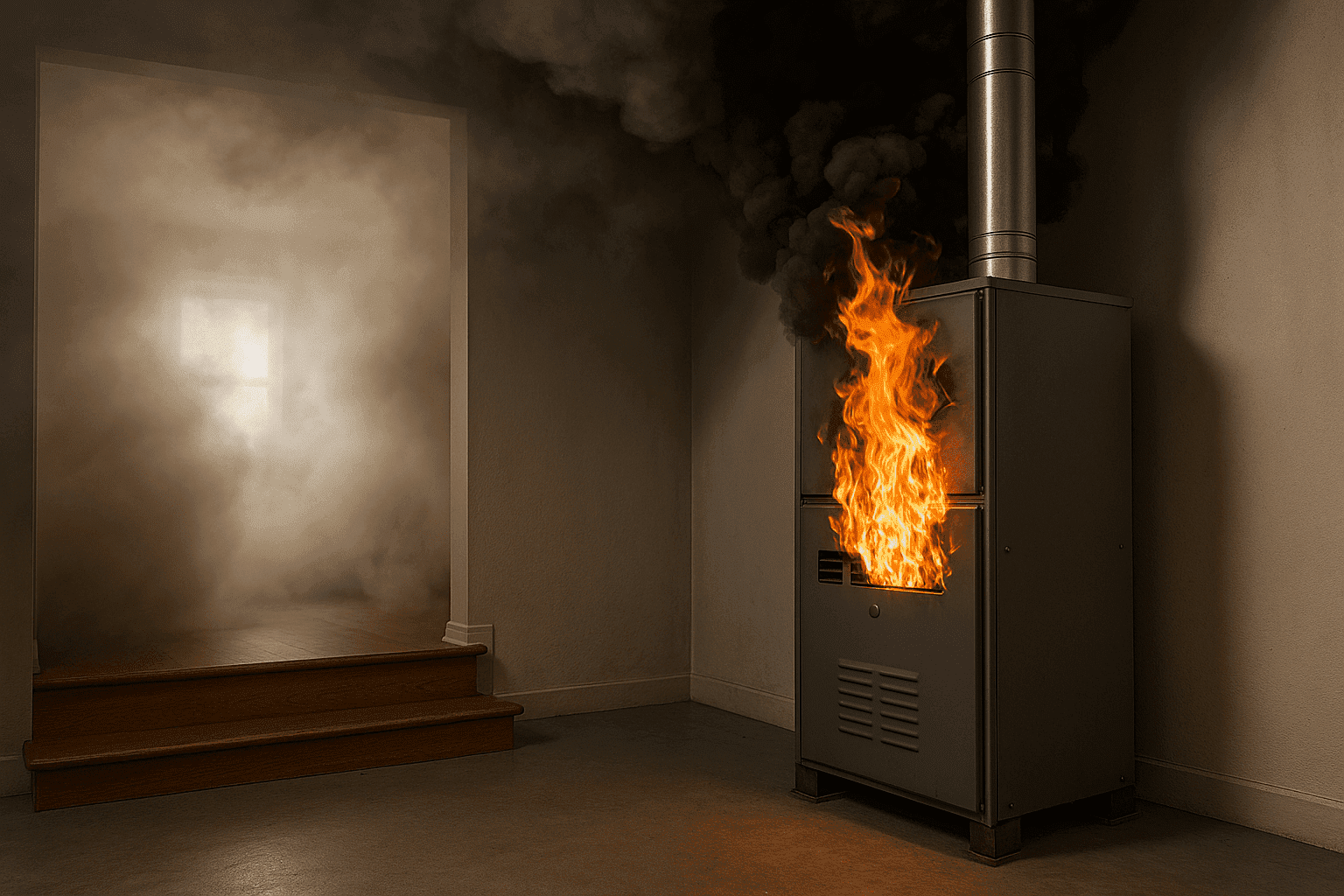

Gas appliance failures cause severe outcomes: property damage, business losses, and life-threatening situations. Forensic investigations are essential to determine causes—from design flaws to maintenance issues. Using principles of thermodynamics, combustion, materials science, and electrical systems, forensic engineers analyze evidence to reconstruct events, prevent future incidents, improve safety standards, and inform legal and insurance processes.

The Investigation Process: Beyond Visual Evidence

From a forensic engineering perspective, initial visual evidence is only the starting point. It leads to a complex technical investigation where unraveling the event sequence requires moving beyond surface appearances. One must systematically analyze the system’s design, operation, and potential failure pathways. A fundamental challenge is determining the initiating event—was it purely related to the fuel gas supply initially, or did another failure precede and cause the gas involvement?

Differentiation of Failure Mechanisms

To differentiate these possibilities, a multi-faceted engineering analysis is required. For instance, an incident originating electrically needs a distinct approach from investigating a primary fuel gas release. This involves carefully examining electrical components such as wiring, connectors, control boards, and motors. Engineers look for evidence of arcing, overheating, or malfunction that could predate the fire or explosion. Specialized techniques like meticulous arc mapping are valuable; by tracing electrical arcs and analyzing characteristics, engineers can pinpoint electrical failure locations and differentiate electrical fault signatures from secondary effects. The challenge of evaluating whether an RTU failure was electrical or from the gas train exemplifies this complexity.

Mechanical and Control System Assessment

Beyond the ignition source, the equipment’s mechanical and control systems must also be thoroughly assessed. An explosion, for example, necessitates a detailed evaluation of specific gas valve assemblies, pressure regulators, or fittings. The goal is to identify potential mechanical failures, material defects, or operational anomalies that could lead to a sudden release or pressure event. This approach differs significantly from tracing a slow leak, which might stem from corrosion or improper fitting installation. Meanwhile, investigating gas furnace incidents often requires in-depth analysis of electronic control systems, including control board logic, sensor inputs, ignition modules, and safety interlocks. Sensor inputs cover flame, temperature, and pressure limits, where engineers search for malfunctions that could create hazardous conditions.

Installation and Maintenance Analysis

A comprehensive engineering investigation also considers the equipment’s installation and maintenance history. Evaluating adherence to codes, standards, and manufacturer specifications during installation provides crucial context, as does reviewing maintenance records and procedures. These records help understand potential contributing factors related to wear, neglect, or improper servicing. Even equipment breakdowns without fire or explosion demand careful analysis to determine if the root cause is mechanical wear, electrical component failure, or control system issues.

Forensic Methodology and Laboratory Examination

Determining cause and origin relies on established forensic engineering methodologies. The process begins with systematic scene documentation and evidence preservation, followed by detailed analysis of physical indicators including fire patterns, heat, and blast effects. Critical components are often subjected to detailed laboratory examination—sometimes called a component autopsy—where the examination looks for subtle failure indicators that might be overlooked during initial scene examination.

Conclusion: Evidence-Based Engineering Approach

In summary, investigating complex gas equipment failures demands a rigorous, evidence-based engineering approach. Moving beyond initial assumptions through detailed analytical techniques accurately determines the event sequence and root cause(s). This technical precision ensures clear, objective findings that explain precisely how and why the incident occurred. If you require expert forensic investigation services for gas equipment failures, contact us today.