Technical Foundation

Generators represent a crucial technology in modern power systems, operating on the fundamental principle of electromagnetic induction. This process involves the conversion of mechanical energy into electrical power through carefully engineered systems and components. Understanding these basics is essential for the proper selection, operation, and maintenance of generator systems.

Core Components and Their Functions

Engine System

The engine serves as the primary source of mechanical energy, converting fuel into rotational force with specific efficiency ratings:

- Diesel: 35-45% thermal efficiency, 0.28-0.32 L/kWh consumption at rated load

- Natural Gas: 25-35% thermal efficiency, 9.5-10.5 kWh/m³ consumption

- Gasoline: 25-30% thermal efficiency, common in units <10kW

- Dual Fuel: Flexibility with a 60-90% gas substitution rate

Alternator System

The alternator transforms mechanical energy into electrical power through electromagnetic induction:

- Rotor: Dynamic impedance 0.15-0.25 p.u.

- Stator: Temperature rise class H (180°C)

- Excitation System: Response time <20ms

- Voltage Regulator: Steady state accuracy ±0.5%

Control System

Modern control systems incorporate:

- Voltage regulation: ±0.25% steady state

- Frequency control: ±0.15% steady state

- Load sharing: ±2% accuracy

- Response time: <100ms

- Data sampling: 1000 samples/second

Auxiliary Systems

Supporting systems specifications:

- Fuel System: 24-72 hour capacity

- Cooling System: 43°C ambient capability

- Lubrication System: 500-hour service interval

- Starting System: 3 start attempts minimum

- Exhaust System: Tier 4 Final compliance

Power Rating Understanding: KW vs. KVA

Fundamental Concepts

Real Power (KW)

- Actual work capability

- Direct correlation to fuel consumption

- Primary sizing factor for resistive loads

- Measurable output power

- Efficiency indicator: 85-95%

Apparent Power (KVA)

- Total power capacity

- Motor starting capability: 3-6 times FLA

- System sizing basis

- Includes reactive component

- Power triangle relationship

Power Factor Relationship

- KW = KVA × Power Factor

- Industrial loads: 0.75-0.85 PF

- Commercial loads: 0.80-0.90 PF

- Data centers: 0.90-0.95 PF

- PF correction benefits: 10-15% capacity gain

Generator Duty Ratings

Standby Power (Emergency) Rating

Definition and Characteristics

- Maximum power: 100% rated capacity

- Annual operation: 200 hours maximum

- Single run duration: 24 hours maximum

- Cool-down period: 48 hours between runs

- Load factor: Maximum 70% over 24 hours

- Response time: <10 seconds to full load

- Voltage stability: ±1%

Applications

- Emergency backup systems (Life safety: 10 seconds)

- Healthcare facilities (NEC 517 compliance)

- Data centers (Tier III/IV: 99.999% reliability)

- Critical infrastructure (N+1 redundancy)

- Commercial buildings (Code compliance)

Operating Parameters

- Load acceptance: 50-60% single step

- Testing: Monthly 30 minutes at >30% load

- Voltage dip: Maximum 15% during loading

- Recovery time: <2 seconds to rated voltage

- Maintenance: Every 200 operating hours

Prime Power Rating

Definition and Characteristics

- Capacity: 90% of standby rating

- Annual runtime: Unlimited

- Overload capability: 10% for 1 hour in 12

- Maximum overload: 500 hours/year

- Load variations: Unlimited within rating

- Efficiency: 85-90% at rated load

Applications

- Construction sites (Temporary power)

- Mining operations (24/7 operation)

- Remote facilities (Off-grid)

- Industrial processes (Variable load)

- Continuous manufacturing (Base load)

Operating Parameters

- Load factor: 70-80% recommended

- Step loading: 30-40% capability

- Maintenance interval: 250 hours

- Oil change: 500 hours

- Major service: 2000 hours

Continuous Power Rating

Definition and Characteristics

- Base capacity: 80% of standby rating

- Operating hours: Unlimited

- Load type: Constant

- No overload capability

- Power quality: ±0.5% voltage

- Efficiency: >90% at rated load

Applications

- Base load power plants

- Continuous industrial processes

- Utility parallel operation

- Constant load facilities

- Process manufacturing

Operating Parameters

- Load factor: 100% continuous

- Step loading: 20-30% capability

- Maintenance: 500-hour intervals

- Expected life: >50,000 hours

- Availability: >95%

Major Manufacturers

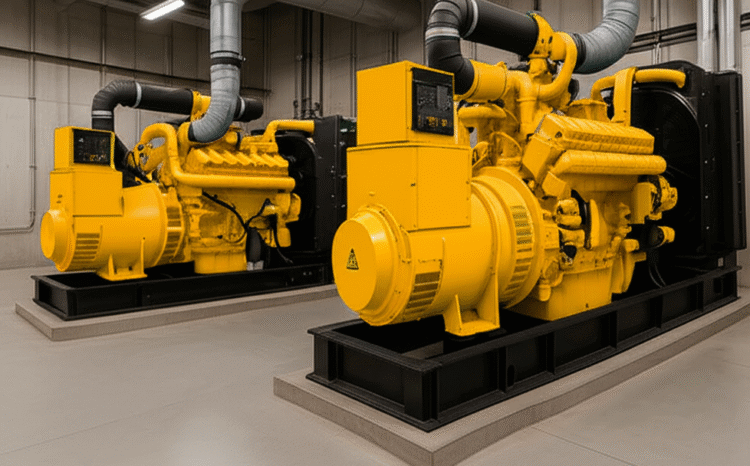

Caterpillar (CAT)

Market Position

- Global market share: 25% industrial

- Geographic presence: 165+ countries

- Price segment: Premium ($$$)

- Product range: 10kW – 17.5MW

- Primary markets: Mining, Oil & Gas

- Parts availability: 24-hour guarantee

- Service network: 2,500+ locations

Design Philosophy

- Conservative rating: 5-10% below competitors

- Reliability focus: 95%+ uptime

- Integrated systems approach

- Comprehensive testing protocol

- Global standardization

Product Features

- Load acceptance: 100% in 10 seconds

- Voltage recovery: <2 seconds

- Parallel capability: Standard

- Digital controls: Advanced

- Remote monitoring: Standard

Cummins

Market Position

- Market share: 20% global

- Coverage: 190+ countries

- Price range: Premium-Mid ($$-$$$)

- Product range: 2kW – 3.5MW

- Focus: Data Centers, Healthcare

- R&D investment: 5% revenue

- Service points: 7,200+ globally

Design Philosophy

- Innovation-driven approach

- Digital integration focus

- Efficiency optimization

- Environmental leadership

- Application-specific solutions

Product Features

- PowerCommand™ platform

- Data center optimization

- Enhanced load acceptance

- Advanced paralleling

- Integrated controls

Environmental Factors

Temperature Impact

- Base rating: 25°C

- Derating above base:

- Standby: 2% per 5°C

- Prime: 3% per 5°C

- Continuous: 4% per 5°C

- Maximum ambient: 50°C

- Cooling system sizing: +15%

Altitude Derating

- Base: Sea level

- Derating per 300m above 1000m:

- Natural aspiration: 3%

- Turbocharged: 4%

- Turbo with intercooler: 2%

- Maximum altitude: 4000m

Selection Guidelines

Technical Assessment

- Load profile analysis

- Peak demand calculation

- Diversity factor: 0.6-0.8

- Growth factor: Minimum 15%

- Starting sequence requirements

- Site evaluation

- Ambient conditions

- Altitude considerations

- Space constraints

- Noise restrictions

Economic Considerations

- Capital costs breakdown:

- Equipment: 40-50%

- Installation: 20-30%

- Infrastructure: 20-30%

- Operating costs:

- Fuel consumption

- Maintenance expenses

- Labor costs

- Parts inventory

Conclusion

Generator selection and operation require careful consideration of multiple factors, including technical requirements, environmental conditions, and economic constraints. Understanding manufacturer differences, rating systems, and application requirements ensures optimal system selection and reliable operation. Regular consultation with manufacturer guidelines and experienced engineers remains crucial for critical applications.